SHREE TMT XTRA 550 – 32mm TMT Bars represent the pinnacle of strength, innovation, and reliability in the construction industry. As one of the largest diameter TMT bars available, the 32mm variant is specifically engineered to handle the demands of massive infrastructure projects and critical load-bearing applications. These bars are the embodiment of advanced metallurgical expertise and cutting-edge manufacturing techniques, ensuring unmatched quality and durability.

With an FE 550 grade, these TMT bars boast exceptional tensile strength and yield stress, making them ideal for large-scale constructions that require superior structural integrity. The bars are equipped with a unique 3X Rib on Rib design, which enhances their bonding with concrete, minimizing slippage and ensuring a secure, stable foundation for your construction projects. Additionally, SHREE TMT XTRA 550 TMT Bars meet the highest standards of the IS: 1786-2008 specifications, ensuring you receive a product that not only performs but also exceeds industry benchmarks.

Key Features of 32mm SHREE TMT XTRA 550 TMT Bars

- FE 550 Grade Strength:

These bars provide the highest level of tensile strength and yield stress, ensuring they can withstand the heaviest loads and most demanding construction scenarios. - 3X Rib on Rib Technology:

The innovative ribbed design significantly enhances the bonding with concrete, ensuring superior grip, reduced slippage, and greater structural stability. - Cost Efficiency:

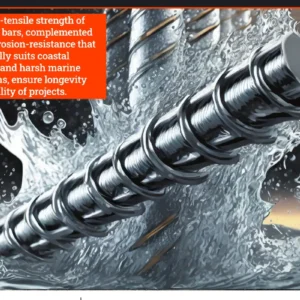

The advanced design and FE 550 grade allow for up to 19% weight savings in construction projects, translating into substantial cost reductions for builders and contractors. - Corrosion Resistance:

Manufactured with a unique chemical composition and treated for rust resistance, these bars offer unparalleled durability, even in environments prone to moisture or harsh weather conditions. - Earthquake Resistance:

The high elongation capacity, achieved through an optimal UTS/YS ratio, ensures flexibility under stress, making these bars ideal for projects in seismic zones. - Eco-Friendly Manufacturing:

SHREE TMT bars are produced using sustainable processes with a reduced carbon footprint, making them a greener choice for environmentally conscious builders. - Unmatched Durability:

These bars are engineered to maintain their structural integrity over decades, ensuring long-term reliability and reduced maintenance costs for your structures.

Applications of 32mm SHREE TMT XTRA 550 TMT Bars

- Bridges and Flyovers:

The exceptional load-bearing capacity and tensile strength of these bars make them a preferred choice for infrastructure projects requiring durability and stability. - Industrial Plants:

Suitable for large-scale industrial constructions, including manufacturing plants, warehouses, and heavy machinery foundations. - High-Rise Buildings:

Ideal for the core structural framework of skyscrapers and commercial complexes where load distribution is critical. - Dams and Power Plants:

Used in projects that demand extreme strength and longevity to support massive loads and withstand environmental pressures. - Mega Infrastructure Projects:

Perfect for tunnels, highways, and other large-scale developments requiring robust materials.

Mechanical Properties of SHREE TMT XTRA 550 TMT Bars

| Grade | Fe 415 | Fe 500 | Fe 550 | SHREE TMT XTRA 550 |

|---|---|---|---|---|

| Yield stress (N/sq.mm) | >415 | >500 | >550 | >550 |

| Tensile strength (N/sq.mm) | >485 | >545 | >585 | >640 |

| Elongation % | >14.5% | >12% | >10% | >16% |

Chemical Properties of SHREE TMT XTRA 550 TMT Bars

| Grade | Fe 415 | Fe 500 | Fe 550 | SHREE TMT XTRA 550 |

|---|---|---|---|---|

| Carbon % | <0.30% | <0.30% | <0.30% | <0.25% |

| Sulphur % | <0.060% | <0.055% | <0.055% | <0.050% |

| Phosphorus % | <0.060% | <0.055% | <0.050% | <0.050% |

| Sulphur & Phosphorus % | <0.11% | <0.105% | <0.10% | <0.10% |

| Manganese % | 0.5%-1.0% | 0.5%-1.0% | 0.5%-1.0% | 0.5%-1.0% |

| CE % | <0.42% | <0.42% | <0.42% | <0.40% |

Weight and Cost Savings with SHREE TMT XTRA 550

| Grade | TMT Fe 415 | TMT Fe 500 | SHREE TMT XTRA Fe 550 |

|---|---|---|---|

| Design strength (N/mm²) | 415 | 500 | 550 |

| Quantity required (MT) | 1,000 | 0.854 | 0.809 |

| % of weight savings | – | 14.6% | 19.15% |

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.